CNC porting machine

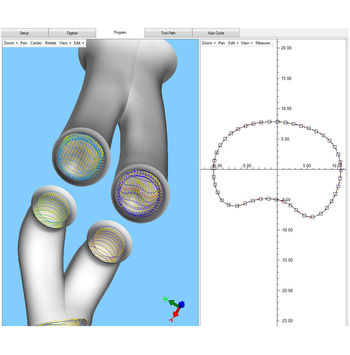

We give a lot of importance to intake and exhaust working ports. We use Rottler’s New P69 5-Axis CNC Cylinder Head Porting Machine, which offers the precision and speed needed to reproduce cylinder heads with exceptional accuracy.

The traditional way

The only way to get that is increasing the flow rate of ports.

Traditionally with a good hand-made job supported by calibrated buffers many "ports tuning Masters" have reached great results. But, although these results are very good, also for these "Masters" is practically impossible to make all the ports perfectly similar and especially it is impossible replicate infinitely the result of their best cylinderheadsWe bought this CNC machining center Rottler P69 to give you a different approach to the problem. The main difference with other 5-axis CNC, of which Italy is full, is the ability to probe your port sections, digitize, and video edit. With port shape digitization, we can evaluate the different areas in the various sections of the port, we can modify or create venturi effect, we can check the distance from collectors to seats and we can also study different shapes.

Basically, changing these values, you can change the characteristics of torque, power, fluidity of the engines. Results are very interesting.

Of course, these works are intended to hi-level engine tuning. Because of that they need studies, fluid-dynamics knowledge and tuning experience. However we suggest that refinement and regularization of the original ports gives significant improvements to the engine, in fact identical ports let breathe all the cylinders the same way, reducing losses of efficiency.

The repeatability of these processes for infinite times is very important too.